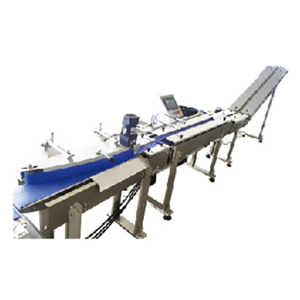

Upper film width:396mmx0.08mm

Lower film width:423mmx0.12-0.21mm

Effective size at work:390mmx384mm

Sealing width:8mm

Yield:4-10cycles/min

Dimension:6570*1016*1850mm

It is suitable for all kinds of leisure food,meat products, seafood, fruits and vegetables, pickles, chilled meat, medical products, hardware components, medical devices, etc.

Suitable for all kinds of foodstuffs, meat products, desserts, seafood, sausages, cheeses, fruits and vegetables, vegetables, frozen foodstuffs, pharmaceutical products, hardware and so on that need vacuum, inflatable, and close-fitting packaging.

The equipment is a full-automatic stretch film vacuum packaging machine developed and produced by the company's technical R &D team. After long-term market research and improvement and Optimization in combination with customer needs,this equipment has become a stretch film automatic packaging equipment with good stability and usability in the current market. The equipment can complete the workflow of automatic forming, heat sealing and cutting; It can be equipped with automatic code printing or automatic codespraying system to truly realize automatic stretch film vacuum packaging.

Controlled by Fuji programmable controller,Fuji frequency conversion speed and color touch screen greatly shorten the operation response time and make the system run more accurate,smooth ,stable and durable; And all safety shields are equipped with magnetic switching devices to better ensure the personal safety of operators.

| Machine mode | DZDL-420 |

| Width of upper membrane | 395 mm |

| Lower membrane width | 422 mm |

| Vacuum degree | ≤200Pa |

| Air pressure | 0.6~0.8Mpa |

| Air flow | ≥0.75m³/min |

| Power Supply | 380V/50HZ |

| Average power | 5.5-6.5 KW |

| Packaging speed | 4-10 Cycles/min (detemined accordng to product characteristcs and feeding speed) |

| Effective size | 384*390mm |

| Sealing form | Gasbag/cyinder |

| Weight of complete machine | ≈1800kg |

| Overall dimensions | 6570mm*1016mm*1850mm(L*W*H) |

-1537.jpg)

.jpg)

-1537.jpg)

GET A QUOTE