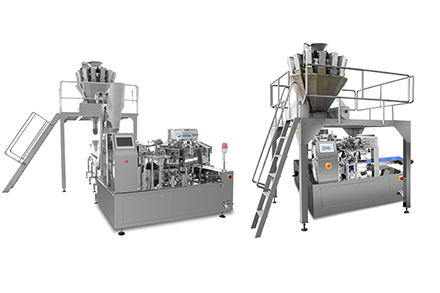

Automatic bagging vacuum packaging machine has two kinds of rotary body composition, respectively, bagging system and vacuum system, referred to as double loading disk. The bag feeding system is intermittent rotary operation; the vacuum system is continuous rotary operation.

ELEMOTION each bag vacuum packaging machine in the preliminary research and development design and later transformation process, abandon the traditional machine on the cumbersome and complex operating steps and buttons, so that each customer in the daily operation of the use of the operation can feel convenient and quick operation of the physical examination.

Machines from ELEMOTION production base from the day of factory, we have continued to follow up until the equipment to complete the commissioning, our customers count to confirm that there is no error before the completion of the first round of services. We have a complete after-sales service system, is committed to solving the customer's worries, the whole service tracking!

ELEMOTION produces automatic bagging vacuum packaging machine can be used for different specifications of vacuum-packed food, to meet the shredded mustard greens, mustard greens core, pickled beans, pickled vegetables, duck necks, chicken wings, marinated eggs, dried tea, duck paws, spicy chicken, dried beans and other packaging needs, to achieve the full automatic lifting, picking up the bag, bagging, marking, opening, propping up the bag, loading, metering, filling, vacuuming, sealing, conveying, etc. until the finished product of the whole Automated packaging production, significantly improve the production efficiency of enterprises. Packaging speed can reach 200 bags / minute, bag width size breakthrough 230mm!

Achieve 100% cleanliness and avoid wrinkles.

Blowing cleaning device ---- To avoid the bag mouth contamination caused by the heat sealing is not firm, crooked (heat sealing line and edge line parallel error more than 2.5mm) and other situations, the equipment is installed with a rotary blowing cleaning device, through the four-way (the center of the two sides of the 45℃ Angle to remove 75% of the dirt, the two sides of the corners of the removal of 25% of the dirt, to achieve 100% clean) blowing pipeline to clean up sealing position attached to the soup or material viscous matter. Outside the cover to avoid splashing debris, clean and tidy. Clean up after the completion of the bag by the first pulling treatment, driven by the transfer cam group to send the bag transfer arm, the process by and clip cam clamping bag mouth to avoid wrinkles, the bag will be transferred to the vacuum cavity, vacuum and sealing.

Sealing without false edges, the pass rate reaches 100%!

Heat sealing ---- In order to avoid bag crease during transferring to vacuum chamber, the bag mouth will be straightened again before heat sealing to ensure that the bag mouth is completely flat. The sealing of the bags is realized by instantaneous high current heating, and then rapidly cooled down by the circulating cooling water, which is returned to the adjustable thermostatic chiller through the pipeline (the temperature deviation value of the thermostatic chiller is lower than 2℃). The average speed of sealing reaches 0.3 seconds/bag, accurate and controllable, sealing without false edges, and the qualification rate reaches 100%.

The service life is up to 70 years with lifetime warranty.

The vacuum system's vacuum closed-air disk device is made of artificial material jointly developed by our company and Germany Igus, which can adapt to the working environment from 50℃ to -32℃, with super wear-resistant skin and a certain degree of elasticity, realizing zero friction and zero abrasion in the process of vacuum packaging. It avoids the problems of adding vacuum paste and lubricating oil for cumbersome maintenance and equipment being worn out when traditional Japanese machines use metal materials. ELEMOTION automatic bagging vacuum packaging machine equipment can be lower energy consumption, to achieve the same vacuum packaging effect with the traditional equipment, and effectively avoid the generation of air bubbles in the vacuum packaging bag.

There are three types of vacuum packaging machines on the market today, in addition to the above automatic bagging vacuum packaging machine, there are also double chamber vacuum packaging machine, rolling vacuum packaging machine. In general, customers can pick the most suitable type of packaging machine according to different types and packaging needs.

Double-chamber vacuum packaging machine: a vacuum chamber in the implementation of vacuum, the other vacuum chamber can be placed to vacuum semi-finished products, effectively saving the waiting time of semi-finished products vacuum, thus improving the efficiency and production capacity, generally applicable to packaging into a “brick” materials, such as rice, chili noodles, etc.

Rolling vacuum packaging machine: rolling vacuum packaging machine sealing line length is generally common 1000mm, 1100mm, 1200mm these specifications. Suitable for larger specifications of products, commonly used in rice and grains and cereals, etc.

In summary, you can clearly know the packaging effect of different vacuum packaging machine and the daily work efficiency and capacity, and then again according to the vacuum packaging machine manufacturers to carry out multi-faceted communication, to choose and buy.

GET A QUOTE